A team of researchers at the National Institute for Materials Science (NIMS) has developed an innovative automated high-throughput system that can rapidly generate extensive datasets from a single sample of a superalloy used in aircraft engines. This groundbreaking system produced an experimental dataset comprising several thousand records in just 13 days, a process that would typically take over seven years using conventional methods.

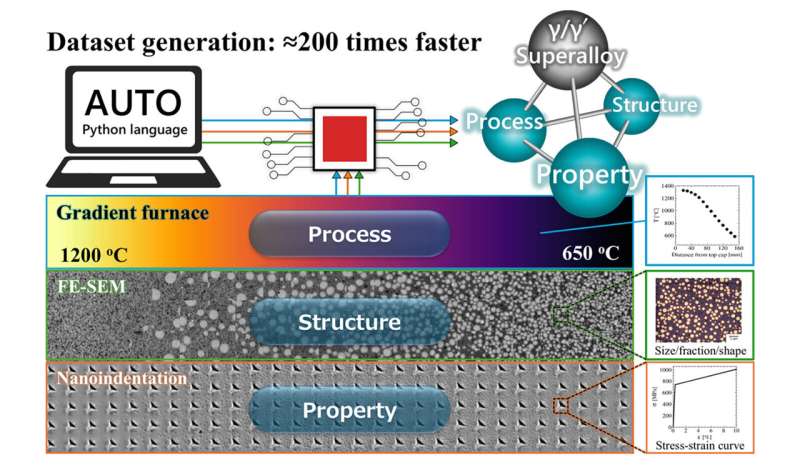

The automated system focuses on creating what are termed “Process–Structure–Property datasets,” which include detailed information on processing conditions, microstructural features, and resulting yield strengths. By significantly accelerating data collection, this advancement holds the potential to transform data-driven materials design.

Accelerating Materials Research

High-precision experimental data is crucial for understanding material mechanisms, developing theoretical models, and enhancing materials innovation. The development of large, accurate Process–Structure–Property datasets is particularly vital for optimizing the complex microstructures and processing methods of heat-resistant superalloys. Traditionally, the creation of such databases has been labor-intensive, requiring substantial time and resources, which in turn has delayed advancements in high-performance superalloys.

The NIMS research team targeted a specific Ni-Co-based superalloy designed for use in aircraft engine turbine disks. Utilizing a gradient temperature furnace developed by the team, they were able to thermally treat the superalloy sample across a range of temperatures. This innovative approach mapped processing conditions while simultaneously capturing microstructural information, such as precipitate parameters, and mechanical properties like yield stress.

The research team employed a combination of a scanning electron microscope, controlled via a Python API, and a nanoindenter to gather yield stress measurements at various coordinates along the temperature gradient. The system’s rapid evaluation and processing capabilities enabled it to generate a substantial volume of data in a fraction of the time required by traditional methods.

Future Applications and Goals

Looking ahead, the team plans to apply the automated high-throughput system to construct databases for various target superalloys. They also aim to develop new technologies for acquiring high-temperature yield stress and creep data. An important focus will be on formulating multi-component phase diagrams, which are essential for effective materials design.

In addition, the researchers are exploring new superalloys with desirable properties through data-driven techniques, with the ultimate goal of fabricating heat-resistant superalloys that could contribute to carbon neutrality efforts. This ambitious aim aligns with global initiatives to enhance sustainability and efficiency in materials used in various industries.

The findings of this pivotal research have been published in the journal Materials & Design. For further details, refer to the article by Thomas Hoefler et al, titled “Automated system for high-throughput process-structure-property dataset generation of structural materials: A γ/γ′ superalloy case study.”

As the field of materials science continues to evolve, innovations like this automated high-throughput system are critical in meeting the demands of modern engineering challenges and advancing the development of future technologies.