The Swiss Federal Laboratories for Materials Science and Technology (Empa) has developed a groundbreaking recyclable epoxy resin that could transform sustainability practices in various industries. This new polymer not only retains essential mechanical properties but also incorporates flame-retardant capabilities, paving the way for its application in areas such as construction and aerospace.

Epoxy resins are widely used in numerous products, from coatings and adhesives to composite materials found in aircraft and wind turbines. However, traditional epoxy poses significant recycling challenges, as it belongs to the category of thermosets. This means that once cured, the long molecular chains are cross-linked in a way that prevents them from being melted down for reuse. As noted by Empa researcher Arvindh Sekar, the options for disposing of epoxy have typically been limited to incineration or landfill.

Innovative Chemistry Behind Recyclability

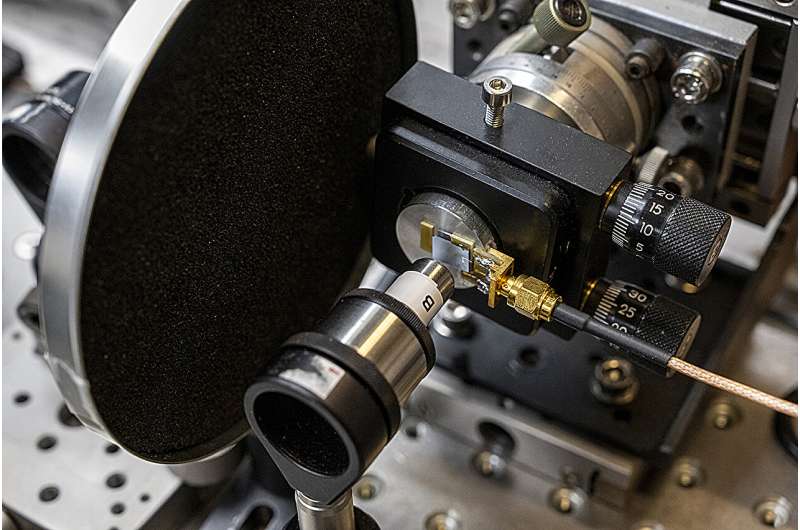

The key to the recyclability of this new epoxy resin lies in its incorporation of phosphorus-containing additives. Sekar explains, “Phosphorus-based additives are commonly used as flame retardants. Normally, they are simply mixed into the epoxy resin as a powder.” The Empa team has innovated by adding a phosphorus-containing polymer before curing, allowing the material to maintain its flame-retardant properties and mechanical strength while enabling the cross-links between polymer chains to rearrange upon heating.

This process, known as thermomechanical recycling, allows the cured epoxy to be ground into powder and reshaped without losing significant mechanical strength. Sekar highlights that the team has successfully conducted ten recycling cycles without any notable degradation in the material’s performance.

In cases where epoxy is part of a composite material and cannot simply be ground down, the new resin offers another advantage. It can be chemically dissolved to recover both the fibers and over 90% of the epoxy along with the phosphorus. Sekar cautions, however, that chemical recycling requires more energy and solvents, and should only be considered as a last resort when thermomechanical methods are not feasible.

Potential Applications and Industry Collaboration

Empa’s research team has been refining this recyclable epoxy resin for several years and has improved the manufacturing process to prepare it for industrial scale-up. Sekar states, “We are looking for industrial partners who would be interested in commercializing the flame-retardant recyclable epoxy.” Initial applications are expected to be in indoor and outdoor coatings, where the new material’s enhanced color stability and reduced yellowing compared to conventional epoxy provide additional benefits.

Another promising application is in the construction of wind turbines, which are susceptible to fire incidents from short circuits or lightning strikes. “In addition to improving fire safety, our material would facilitate maintenance and component replacement because it can be reshaped under the right conditions even after curing,” Sekar adds.

As the researchers continue to explore combining the phosphorus additive with other polymers, the potential for developing fire-resistant and recyclable materials expands further. The findings are detailed in the Chemical Engineering Journal, contributing to the ongoing conversation about sustainable materials and their role in mitigating environmental challenges.

For now, the development of this recyclable epoxy resin represents a significant step toward reducing plastic waste and enhancing the sustainability of materials used in critical applications worldwide.