A research team from the East China University of Science and Technology has created an innovative AI-assisted materials-genome approach that significantly advances the design of high-performance polyimide films. This breakthrough, published on September 2, 2025, in the Chinese Journal of Polymer Science, addresses the longstanding challenge of optimizing mechanical properties in polyimides, which are vital for applications in aerospace, flexible electronics, and micro-display technologies.

Polyimides are renowned for their thermal stability and insulation properties. However, the mechanical optimization of these materials has proven difficult. Traditional methods often involve a trial-and-error process that can be both time-consuming and expensive. Compounding the issue, improvements in one property, such as modulus, typically result in a decrease in another, such as toughness.

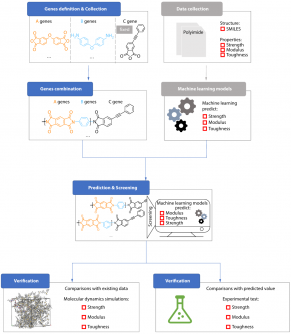

The newly developed strategy employs machine learning to predict three crucial mechanical parameters—Young’s modulus, tensile strength, and elongation at break—across thousands of potential polyimide structures. This approach provides a systematic and high-throughput way to identify formulations that exhibit superior mechanical performance.

The team utilized Gaussian process regression (GPR) models trained on over 120 experimental datasets of polyimide films. By treating the structural fragments of each polymer—specifically dianhydride, diamine, and end-capping units—as “genes,” they explored a vast chemical space of 1,720 phenylethynyl-terminated polyimides (PPIs). These models achieved high predictive accuracy, with R² values between 0.70 and 0.74 for all three mechanical metrics.

Among the significant findings was the identification of a new formulation, PPI-TB, which surpassed the performance of established benchmark polyimides. Molecular dynamics simulations confirmed that PPI-TB (gene combination A4/B32) exhibited a modulus of 3.48 GPa, along with enhanced toughness and strength indicators when compared to systems like PETI-1 and O-O-3.

Further experiments demonstrated a strong correlation between predicted and measured data, reinforcing the validity of the AI-driven approach. The research highlighted essential design principles, such as the role of conjugated aromatic structures in enhancing stiffness and how the inclusion of heteroatoms and heterocycles can strengthen molecular interactions. Additionally, incorporating flexible silicon- or sulfur-containing units was shown to improve elongation.

Prof. Li-Quan Wang, one of the study’s corresponding authors, emphasized the transformative potential of this work: “By translating polymer fragments into genetic-like descriptors, we can treat molecular design like decoding a genome. Machine learning not only predicts performance but also reveals which chemical ‘genes’ are driving it.” He noted that this integration of data science and chemistry allows for exploration of material possibilities that would take decades using traditional methods.

The AI-driven materials-genome strategy offers a scalable framework for designing polymers with targeted combinations of stiffness, strength, and flexibility—essential traits for applications in microelectronics, aerospace composites, and flexible circuit substrates. By replacing extensive experimental iterations with predictive modeling and virtual screening, the method significantly reduces both costs and development time.

While the focus has been on polyimides, the workflow developed through this research holds promise for adaptation to other high-performance polymer classes. This could facilitate the creation of lightweight, durable, and thermally stable materials that will underpin the next generation of electronic and aerospace technologies.

The project received financial support from the National Key R&D Program of China (No. 2022YFB3707302) and the National Natural Science Foundation of China (Nos. 52394271 and 52394270), underscoring its significance in advancing materials science.