The integration of advanced technologies such as robotics and smart CNC controls in manufacturing does not diminish the importance of tool geometry. Despite the sophistication of automated systems, the fundamental aspects of cutting tools, including helix angles and edge preparation, continue to play a pivotal role in the efficiency and quality of machining processes.

Understanding the Role of Tool Geometry

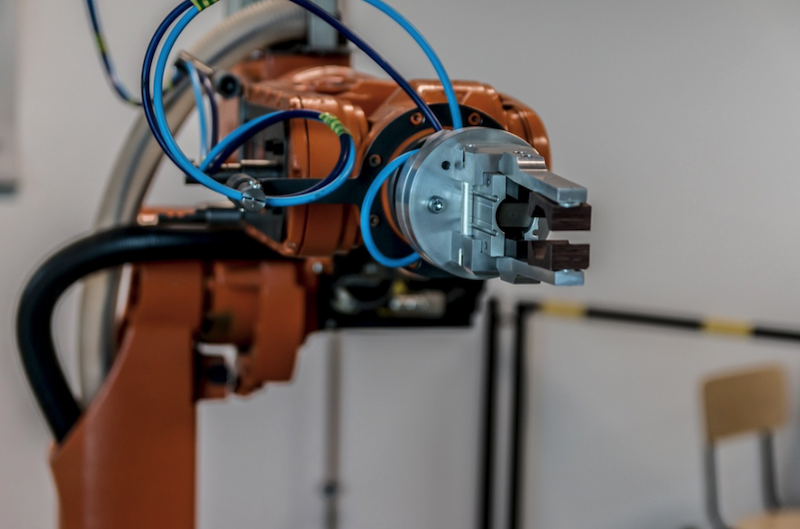

In modern manufacturing environments, robots are increasingly responsible for loading parts while CNC controls dynamically adjust feeds and speeds. While these innovations suggest a shift in focus from tooling to software, the reality is that the cut still occurs at the contact point between the cutting tool and the workpiece. As a result, decisions regarding tool geometry remain crucial.

Research indicates that parameters such as helix angles, rake angles, and flute count significantly influence cutting forces, heat generation, and chip flow. When these fundamental aspects are not optimized, even the most advanced systems struggle to maintain stable and productive operations. For instance, a well-structured project in the realm of Industry 4.0 typically assumes that the cutting tools employed are suitable for the tasks at hand. According to the National Institute of Standards and Technology (NIST), AI-enhanced analytics can improve processes but cannot compensate for poor geometry choices.

The Impact on Production Efficiency

In environments like job shops, where the machining of varied materials occurs regularly, geometry choices directly affect operational flexibility. For example, minor adjustments in tool parameters can lead to significant changes in cutting forces and surface finish. A recent study highlighted that optimizing tool micro-geometry can lead to reduced cutting forces and improved surface quality, thereby enhancing tool life across different operations.

The nuances of tool selection demand careful consideration. A typical carbide end mill, despite sharing nominal dimensions, can behave very differently based on its geometry. A polished, high-helix 3-flute tool will generally perform better in aluminum applications compared to a standard 4-flute design. Such differences can lead to operational challenges, especially in robot-assisted setups where the automation does not accommodate errors as a human operator might.

The reliability of robotic systems depends heavily on the robustness of the process. For instance, when machining hard stainless steel, using a tool with a small corner radius minimizes the risk of chipping, thereby extending tool life and maintaining dimensional accuracy. A robot’s inability to adjust for unexpected tool wear or chipping highlights the necessity of selecting appropriate geometry from the outset.

In addition, flute count and chip clearance are critical in high-feed strategies. A tool with insufficient gullet space may create excessive heat and lead to chatter, ultimately compromising the machining process. The efficiency of robots is determined not only by their programming but by the underlying geometry of the tools they utilize.

Strategies for Optimizing Tool Geometry

To maximize the benefits of advanced CNC and robotics, manufacturers must prioritize informed tool geometry decisions. Standardizing tool families based on material and operation, rather than solely on diameter, is a practical first step. For example, specifying high-helix, polished 3-flute tools for aluminum and low-helix multi-flute designs for hard steels ensures that the right tools are available for each job.

Moreover, integrating geometry assessments into process approval workflows is essential. When introducing new parts into robotic cells, it is vital to evaluate not only the feeds and speeds but also critical geometry factors such as helix angle and flute count. Questions should focus on whether the selected configurations can effectively clear chips and withstand the planned cutting conditions.

Finally, manufacturers should document and analyze successful geometry configurations. When specific tools consistently yield better results, those insights should shape future tool selection and standard practices. Over time, this approach will foster a library of effective geometries that align with the automated processes being scaled.

In summary, while advancements in CNC controls and robotics can enhance manufacturing processes, they are only as effective as the tools employed. Treating tool geometry as a primary design consideration rather than an afterthought will ensure that manufacturers maximize the potential of their automated solutions.