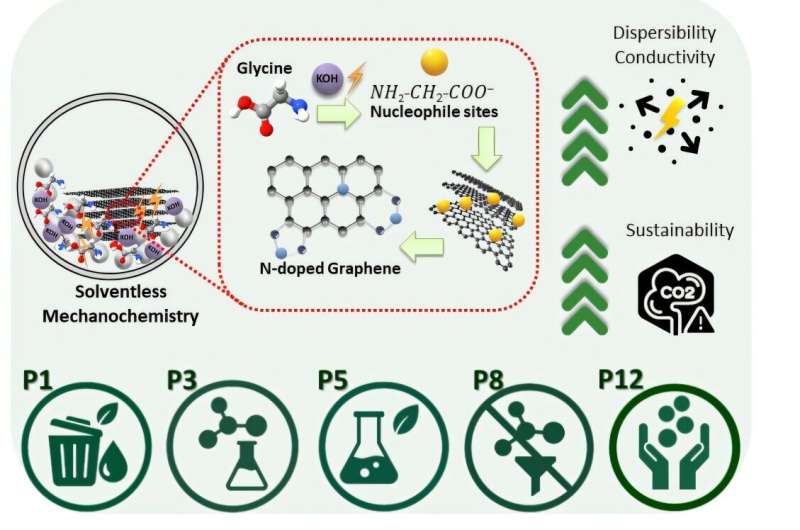

Recent research has unveiled a groundbreaking method for producing nitrogen-doped graphene nanoplatelets (N-GNPs) using a sustainable, solvent-free approach. Led by Chamalki Madhusha and her team at Monash University, the study, published in ACS Sustainable Chemistry & Engineering, addresses the pressing challenge of developing advanced materials with minimal environmental impact.

Graphene, often hailed as a “wonder material,” boasts remarkable properties such as strength, electrical conductivity, and thermal efficiency. Despite its potential, many graphene-based technologies have struggled to transition from laboratory settings to practical applications. A primary hurdle has been the difficulty in functionalizing graphene to enhance its properties for various uses, including smart coatings and conductive composites.

The conventional methods of functionalizing graphene, particularly through nitrogen doping, often involve toxic precursors and extensive purification processes. These methods typically require high temperatures, multi-step procedures, and generate significant chemical waste, raising concerns about their sustainability.

In response to these challenges, Madhusha and her colleagues turned to mechanochemistry, a technique that harnesses mechanical forces to drive chemical reactions without the need for solvents. By employing a ball-milling process, the researchers successfully functionalized graphite with a bio-derived nitrogen source, specifically amino acids, under ambient conditions. This innovative approach not only eliminated the need for harsh chemicals but also significantly reduced energy consumption during production.

The outcome of this research yielded nitrogen-doped graphene nanoplatelets that retained high electrical conductivity and good dispersibility, effectively addressing two major challenges in graphene processing. The team achieved a remarkable material yield of approximately 80%, showcasing the efficiency of their solvent-free method.

Sustainability Metrics and Material Performance

To assess the sustainability of their production process, the researchers implemented both qualitative and quantitative measures. The E-factor, a standard metric in green chemistry that quantifies waste generated per unit of product, revealed that their method produced significantly less waste compared to traditional graphene functionalization strategies. By removing solvents and high-temperature post-annealing steps, the overall energy demand was also reduced, underscoring the importance of process design in enhancing the sustainability of advanced materials.

The incorporation of nitrogen atoms into the graphene lattice can alter the material’s electronic properties, potentially enhancing its conductivity and chemical reactivity. The N-GNPs developed in this study not only maintained structural integrity but also exhibited improved performance in terms of electrical, thermal, and mechanical properties when used as nanofillers in composite systems.

Implications for Future Materials Development

One of the most promising applications of N-GNPs is their compatibility with vitrimers, a class of polymers known for their mechanical strength and reprocessability. When integrated into vitrimer matrices, these nitrogen-doped nanoplatelets can serve as multifunctional fillers, enabling electrically triggered self-healing capabilities and enhancing overall material performance. This innovation paves the way for the development of repairable coatings and recyclable composites, where both performance and sustainability are paramount.

The broader implications of this research extend beyond graphene. Many high-performance materials are still produced using outdated methods that do not prioritize environmental considerations. Madhusha’s work emphasizes the necessity of integrating green chemistry principles at the design stage, leading to reduced waste and lower energy use.

As industries in electronics, aerospace, and energy storage increasingly prioritize sustainable practices, the findings from this research highlight the potential for more environmentally friendly manufacturing processes. The ability to create advanced functional materials through sustainable synthesis strategies will be crucial as demand continues to grow.

Looking ahead, the team plans to explore how their mechanochemical approach can be adapted for further applications, including other dopants and scalable manufacturing routes. The commitment to advancing both materials performance and sustainability is essential for shaping the technologies of tomorrow.

This study exemplifies a significant stride towards aligning nanomaterial innovation with sustainability goals. As the landscape of advanced materials evolves, the integration of environmentally conscious methods will play a pivotal role in their development and application.